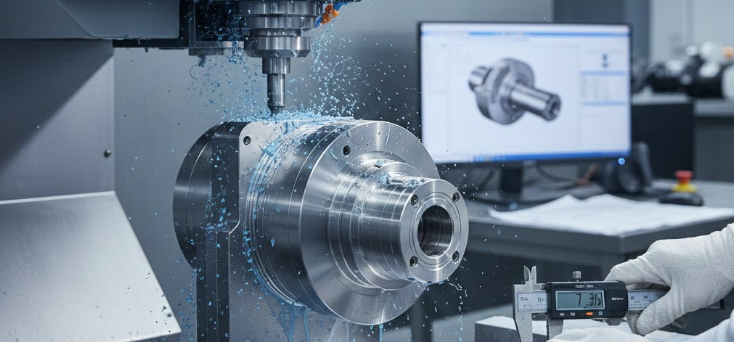

Today, in the world of manufacturing, the terms precision and accuracy are indispensable in the production of high-quality components having tight tolerances and perfect surface finishes. The right machining coolant, albeit being one of the most powerful yet frequently neglected factors, has a significant impact on the performance level. The tool life, machining speed, heat control, chip removal, and quality of the product are all directly influenced by the choice of coolant. The machining process can be very efficient and reliable, depending on the coolant used, if working with aluminum, steel, titanium, or even exotic alloys. That’s why it is wise to cooperate with a trustworthy precision machining company India that is always able to select the appropriate coolant, thereby guaranteeing superior performance and uniform results.

What is Machining Coolant & Why Is It Important?

Machining coolant is a unique mix of fluid specifically meant for CNC and precision machining operations. It manages to cool down the tools, reduce the friction, and even wash out the chips during cutting, drilling, milling, or grinding. If the coolant is not controlled properly, the heat that is built up can get so high that it wears down the tool, causes errors in dimensions and produces poor quality surface finish. Coolant also acts as a rust preventer and a machine health improver. A trustworthy precision machining company applies the right coolant to keep the operation steady and prolong the machines’ lifespan.

The main functions of the machining coolant are:

- Heat dissipation and stability of the temperature

- Lubrication for cutting without any difficulties

- Removal of chips leading to uninterrupted machining

- Rusting and bacterial contamination stoppage

How Coolant Affects Precision Machining Performance

The use of coolant directly affects the efficiency, accuracy, and quality of the machining operations in a positive way. The proper coolant not only enhances the cutting stability but also allows the machining speeds to be increased and the life of the tool to be prolonged. The selection of an inappropriate coolant will result in tool failure, poor surface quality, and a higher amount of scrap produced, which will all negatively affect productivity.

Among the performance advantages are:

- Dimensional accuracy and tolerance control improved

- Feed rates and spindle speeds increased

- Vibration, heat stress, and surface defects are minimized.

- Operation stability for demanding materials and high-volume production

Types of Machining Coolants

Different coolant formulations are applied depending on the material, process type, required finish, and equipment. A specialist precision machining company chooses the coolant according to the performance requirements and the environmental impact of the process.

Common types of machining coolants:

- Soluble Oils: Greatly reduce friction; tough cutting work is their application area

- Semi-Synthetic Coolants: Generally provide more lubrication and cooling, and the application area is the widest

- Synthetic Coolants: Heat conducting is the main asset of this type; it can support fast machining

- Straight Oils: Suitable for grinding, deep drilling, and superfinishing

Key Factors to Consider When Choosing Machining Coolant

The choice of coolant has to be in harmony with the process complexity, production objectives, and the needs of the part. A wrong selection can result in either tool failure or part rejection.

The main selection factors:

- Materials from aluminum, steel, titanium, nickel alloy,s and brass

- Process of making, turning, milling, grinding, and drilling

- Surface finish and dimensional tolerance requirements

- Temperature, machine type, and cutting speed

- Filtration and machine components’ system compatibility

Coolant and Tool Life: Relationship Explained

The function of coolant is crucial in the sense that it lowers the temperature and the friction of the cutting tool and the workpiece. A combination of different coolants and effective cooling might completely stop the cutting edge from being broken down, would make the tool coasting to be used longer, and, besides, would allow for the intervals of replacing tools to be reduced thus saving costs on the overall production.

The optimization of tool life gives the following benefits:

- Decreased thermal cracking, chipping, and abrasive wear

- Longer periods between tool changeovers

- Greater uptime and fewer interruptions

Coolant’s Role in Achieving High Surface Finish & Dimensional Accuracy

With the help of a top-notch machining coolant, there is smooth chip flow, temperature control, and proper lubrication, which in turn gives cleaner surface finishes and tighter tolerance stability.

Surface quality benefits:

- Burr formation and surface roughness are minimized

- Distortion and thermal expansion are controlled

- Consistency of micro-level finishing for critical components is achieved

Impact on Machine Productivity & Cycle Time

The correct coolant improves the operational efficiency and reduces the production time through faster and cleaner cuts.

Productivity gains:

- Increased cutting speeds and feed rates

- Tool change frequency decreased

- Downtime due to chip clogging and overheating has been reduced

How Coolant Selection Helps Reduce Operational Costs

The strategic selection of coolant directly affects the cost savings and the manufacturing value in the long term.

Factors that lead to saving costs:

- Maintenance of tools and machines at lower expenses

- Lower scrap and defect rates

- Coolant life prolongation through stable concentration control

Coolant Maintenance & Concentration Management

It is important to monitor and take care of the coolant, even if it is the best one. A well-experienced precision machining company keeps an eye on the coolant concentration to prevent any risks related to dilution and contamination.

Maintenance practices:

- Testing of pH and concentration at regular intervals

- Filtration and getting rid of tramp oils

- Replacement of coolant and cleaning of tanks as per schedule

Coolant Rapport & Environmental Safety

Selecting a coolant that is safe for the workers, machines, and disposal regulations is a must for the sustainability of the workplace.

Safety factors:

- Non-toxic and low odor chemical formulation

- Low volatile emissions and bacterial resistance

- Adherence to environmental disposal standards

Common Coolant Problems & Troubleshooting

If the coolant failure is not detected at an early stage, it will cause issues in both the quality and productivity of the process.

Some of the typical problems are:

- Foaming, smell, or too much smoke

- Rust, residue formation, bacteria growth

- Poor lubrication or a color change of the coolant

How a Precision Machining Company Ensures the Right Coolant Selection

Machining specialists with long-standing experience constantly analyze the process requirements and the coolant performance to achieve high machining accuracy all the time.

The best practices for selecting the right coolant are:

- Evaluating the coolant performance according to the material used and the speed applied

- Keeping a check on the concentration and the quality of the filtration

- Opting for trustworthy suppliers and environmentally friendly solutions only

Conclusion

The selection of the coolant is one of the factors that will determine the performance of the machining process. It will affect the life of the tool, the quality of the surface, the precision of the dimensions and the efficiency of the whole operation. In case you manufacture aerospace parts or industrial components, the right coolant will make the machining process smooth, accurate, and cost-efficient. The collaboration with a skilled precision machining company guarantees the expert coolant choice, preventive measures in the maintenance process, and excellent machining results. Intelligent coolant choices result in better output, fewer stoppages of the machine, and continuous good quality results.

FAQs

What type of coolant is best for CNC precision machining?

Semi-synthetic coolant provides the right amount of cooling and lubrication, thus the perfect candidate for CNC precision machining applications.

How often should coolant be replaced or monitored in machining operations?

Coolant concentration and quality should be checked weekly and replaced according to performance, contamination levels, and usage.

Can the wrong coolant cause damage to tools or machines?

Yes, inappropriate coolant results in corrosion, overheating, tool failure, poor finish, and higher maintenance costs.

How do different coolants affect surface finish and tolerance accuracy?

The cooling and lubrication efficiency of coolants is different, thereby impacting smoothness, dimensional control, and cutting stability.

What practices should a precision machining company follow to maintain coolant quality?

Regular testing, filtration, concentration control, bacterial treatment, and scheduled coolant replacement keep up high operational performance.