Techniques in agriculture today actually rely on the use of technology that improves productivity, efficiency, and sustainability at the same time. Hydraulic systems are one of the most important innovations in modern agriculture, as they are the source of power for all kinds of machines, from tractors to harvesters. A good hydraulic part manufacturer guarantees a smooth operation of these machines and provides the power and accuracy needed for the strenuous work on the farm.

Manufacturers, by means of providing strong hydraulic cylinders, pumps, valves, and fittings are the ones to lead the change in agriculture from the traditional ways to the mechanized ones with high speeds—their support to the farmers is by way of yielding more with less labor and less downtime, simultaneously facilitating the growth of the modern agriculture sector that is driven by technology.

Do you hear Hydraulic Systems in Agriculture?

Agricultural hydraulic systems are technologies that power heavy-duty operations through the use of pressurized fluid, thus performing such operations painstakingly and economically. The systems take mechanical energy and convert it into hydraulic power, thus giving the machines’ arms the freedom to lift, push, or pull, and with the precision of a surgeon to control them. A reliable manufacturer of hydraulic pump parts builds such systems that can endure the toughest of conditions in the field and at the same time perform well at any farm application.

Main features of agricultural hydraulic systems:

Power transmission: Fluid under pressure is used to operate or control the mechanical parts with high efficiency.

Versatility: Shown in tractors, loaders, sprayers, and harvesters, which can perform various roles.

Precision control: Very accurate lifting, steering, and motion control of the equipment are made available.

Stability: Designed for the hardest environments, high temperatures, and rough terrains.

Why Hydraulics Are Important to Agricultural Activities

The use of hydraulics is a major factor in the modern agricultural equipment being operated with great accuracy and also with a lot of power. The hydraulic parts supplied by a trusted manufacturer guarantee that the very demanding nature of the farm work will not affect the operation, efficiency, and reliability of the equipment.

Main Advantages:

High Power Output: It produces a great force that can be used for lifting, digging, and steering.

Precision Control: It gives very small and accurate movements in tractors and harvesters.

Efficiency: It is an energy-efficient system that also lowers the costs of fuel and maintenance.

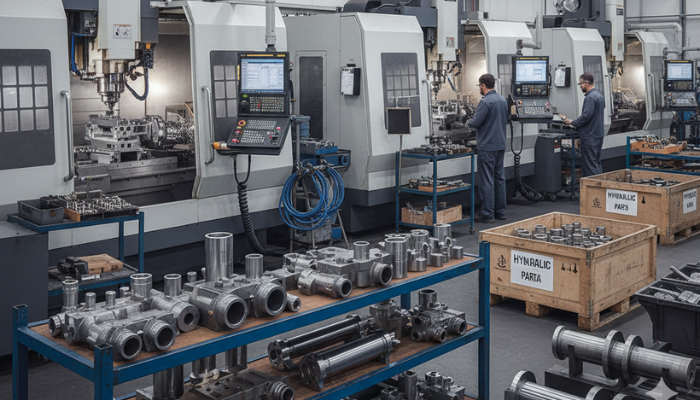

The Role of a Hydraulic Part Manufacturer in Agriculture

The maker of hydraulic parts is one of the most important players in modern agriculture. Their high-performance components keep the farming machines working efficiently and reliably. The hydraulic part manufacturers make sure that all the hydraulic systems are working well, and they do so by supplying power and providing precision for the essential agricultural operations.

Main Roles and Offerings:

Design: Imagine and produce hydraulic pumps, cylinders, valves, and fittings that are completely unique. For agricultural machines.

Support and Care: Offer technical support and supply spare parts in order to reduce as much as possible the time for which the equipment is out of service.

Key Hydraulic Components Used in Agricultural Machinery

For the execution of heavy-duty and multi-faceted operations, agricultural machines make use of components that are precisely engineered. A hydraulic parts manufacturer renowned in the industry provides such parts that are essential, thus allowing the perfect operation, long life, and high power in every application on the farm.

Major Areas of Hydraulic Components with Their Functions:

Hydraulic pumps: The hydraulic pumps transform the force they store from one end and convert this energy out by inputting it through the hydro-motor, thereby performing the hydraulic work.

Hydraulic Cylinders: As creators of the necessary linear motion, they do this for plowing, lifting, and harvesting.

Hydraulic Motors: Their task is that of turning and making the rotors, and the other tools which are very much attached, to be operated.

Seals and Gaskets: Their primary duty is to block the escape of fluids, thus helping to maintain the pressure in the system and the lifespan of it too.

Applications of Hydraulics in Farming Equipment

Hydraulic systems are the heart and soul of modern agricultural machines, powering and controlling at the same time. Dependable suppliers of hydraulic parts guarantee that every single piece works in an efficient way for different applications, thus making productivity and operation easy in the field.

Tractors: powering steering, lifting attachments, and controlling tools. Such, e.g., an electrical tractor is a power draw where farmers can easily switch and control the tools according to their needs.

Harvesters: driving blades, moving materials, and unloading grains. The modern, e.g., such as the case of a harvester with high technology, is so advanced that it requires just the press of a button to control its functions.

Irrigation Systems: the path of water is determined, and pressure on different areas is applied by using hydraulic pumps.

Innovations by Modern Hydraulic Part Manufacturers

Hydraulic parts manufacturers at the forefront of the industry are progressively incorporating state-of-the-art technologies to not only enhance but also to render farming tools more eco-friendly and smart. Among the benefits of these innovations are the better performance of machines and lower maintenance costs for the farmers.

Key Innovations:

Smart Hydraulics: Merging of devices and the Internet of Things for monitoring performance in real time.

Energy-Efficient Systems: The use of advanced designs that lead to a reduction in fuel consumption and fluid loss.

Automation Support: Interoperability with smart farming and automated machines.

Quality, Testing, and Reliability: The Manufacturer’s Responsibility

Among the hydraulic parts manufacturers, one with a good reputation makes sure that every single part goes through the highest quality, safety, and durability standards. Well, the testing procedures have been really complete, and this made it possible for hydraulic components to work without any problems, even when the agricultural environment was very harsh.

Reasons for Quality and Reliability:

Material Strength: Corrosion-resistant metals and alloys are used, thus products become more durable.

Performance Testing: The product is subjected to pressure, temperature, and endurance tests, and only then is it released.

Leak-Proof certainty: The application of cutting-edge sealing technology guarantees the product’s durability.

Precision Engineering: The careful conception ensures that the component fits without interruption with the agricultural machines.

Certifications: The products are subjected to rigorous testing and granted approval as per ISO and other reliability standards of the industry.

Hydraulic Systems that Support Sustainable Agriculture

Current hydraulic component producers engage in sustainable farming by designing systems that use less power and cause minimal impact on the environment. Today’s hydraulic systems not only increase the efficiency of industrial machines but also make agriculture more eco-friendly.

Green Advantages:

Less Fuel Consumption: The incorporation of energy-saving hydraulic machines in the production process will also result in a significant decrease in operating costs.

Reduced Emissions: The better systems are a part of agriculture that is less harmful and more eco-friendly.

Longer Equipment Life: The manufacturers of durable parts create less trash and need to do fewer replacements.

Eco-Safe Materials: The use of hydraulic oils that are non-toxic and recyclable is approved.

Resource Efficiency: The accurate control system will eliminate the use of extra water and fertilizers.

A collaboration among farmers, OEMs, and hydraulic parts manufacturers

Technology and performance will be integrated in the best possible way through the joint effort of farmers, OEMs, and hydraulic parts manufacturers. The presence of such partnerships will bring about the ultimate innovation and reliability throughout the agricultural industry.

Main interaction areas:

Custom Solutions: Hydraulic parts specifically made for certain machines and field conditions.

Technical Support: Ongoing support and maintenance suggestions for the users.

Product Development: The product’s usability and adaptability will be guaranteed through creative collaboration.

After-Sales Service: Spare parts and performance upgrades will be provided quickly.

Training Programs: Farmers and technicians will be trained in hydraulic systems.

Selecting Hydraulic Parts Manufacturer: Criteria to Keep in Mind

The significant role that picking the right hydraulic parts manufacturer plays in yielding the utmost durability, optimum performance has a long-lasting and the most economical way. The proper partner will provide not only the technical know-how but also the flexibility and support in the post-sale phase to be able to overcome the agricultural challenges.

Selection Checklist:

Experience & Reputation: Evident past performance in agricultural hydraulic systems.

Technical Skills: Professional engineers and creative manufacturing plants.

Cost Effectiveness: Affordable prices, and at the same time,e no performance loss.

Conclusion

Hydraulic technology is the core of today’s eco-friendly and effective agriculture. A credible hydraulic parts manufacturer gives the agricultural machines the durability and precision of the components so the machines can operate under strong and accurate conditions. A company like APCPL Group, among others, that ensures quality, innovation, and sustainability, is a supporter of farmers globally. All that is left is to improve productivity, less downtime, and adopt environment-friendly methods, which are the future of sustainable agriculture.